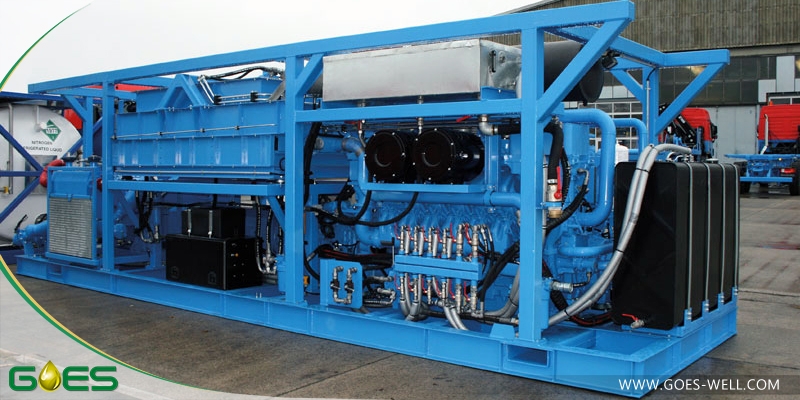

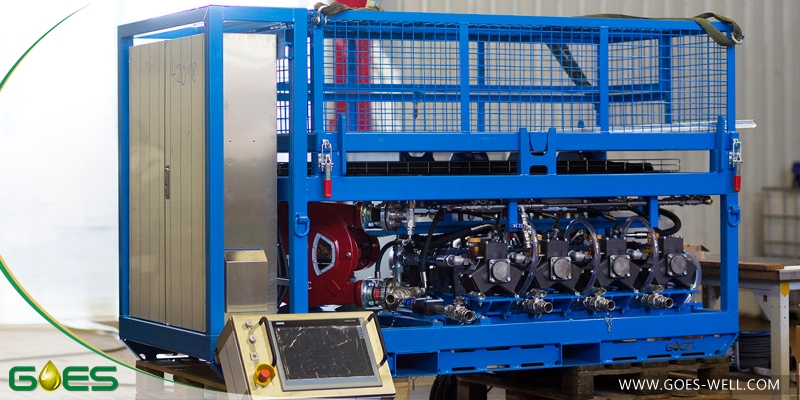

Understanding that different environments and road regulations require different designs, GOES frac equipment is available in truck, trailer and skid mounted versions.

Various designs for different types of units are available, and if the customers are looking for customization, our experienced in-house engineering team will make sure that the requested design will also be accomplished.

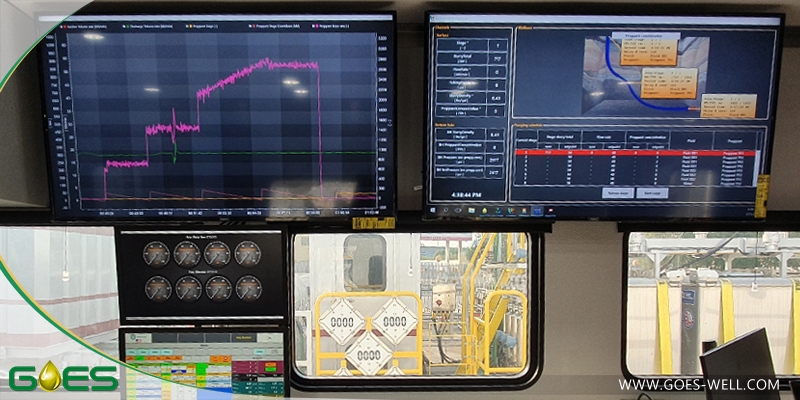

An open and flexible control system makes sure that your operators can easily be trained on our SIEMENS based control system. Control systems include analog, digital and remote options. Upon customer request, we have the ability to install the controls of their choice.

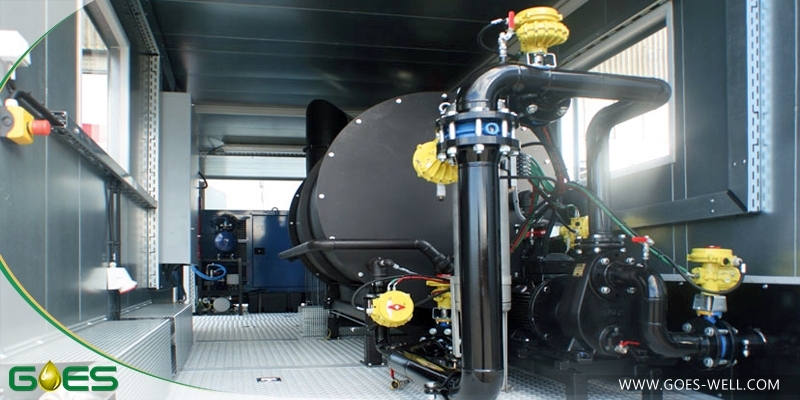

All well stimulation equipment is available for onshore and offshore applications and are coming with the requested certificates.