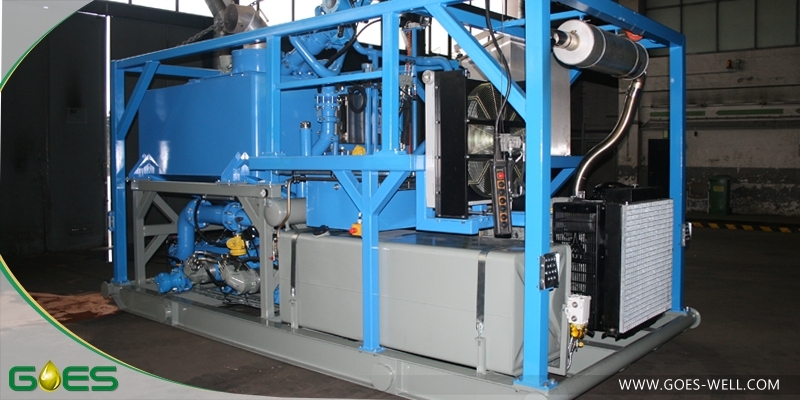

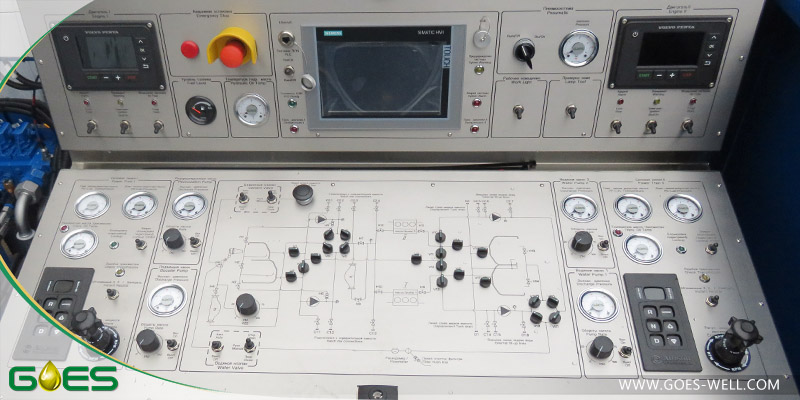

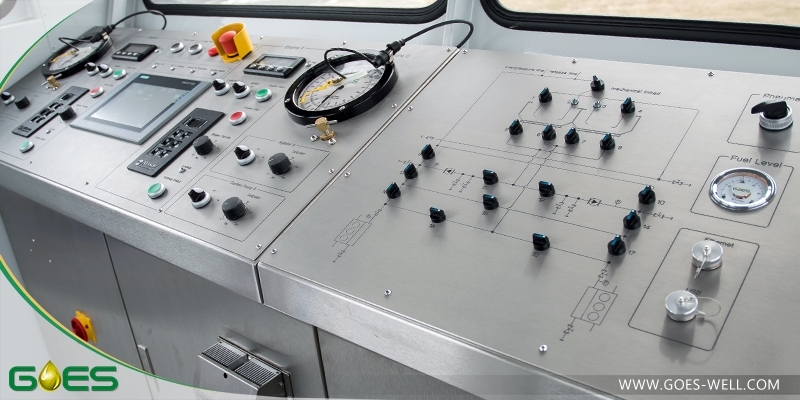

Depending of the application, the units can be ordered as a skid, trailer or truck-mounted system.

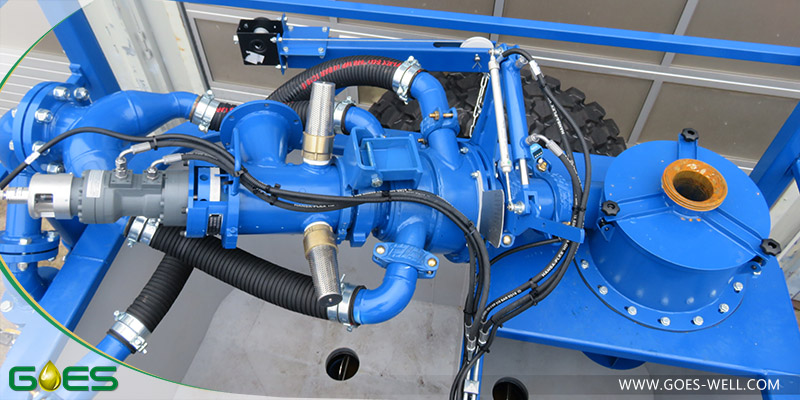

Our fluid pump skids are available with DNV 2.7.1 and ATEX certifications. GOES oilfield units can all be ordered with CE marking. Main components can be chosen by the customer, but standard packages are also offered.

Truck mounted designs can be ordered with a deck-engine or with a cost and weight-saving set up where the road engine is used also for the pumping application. Each unit is available as a twin fluid pumping system too.