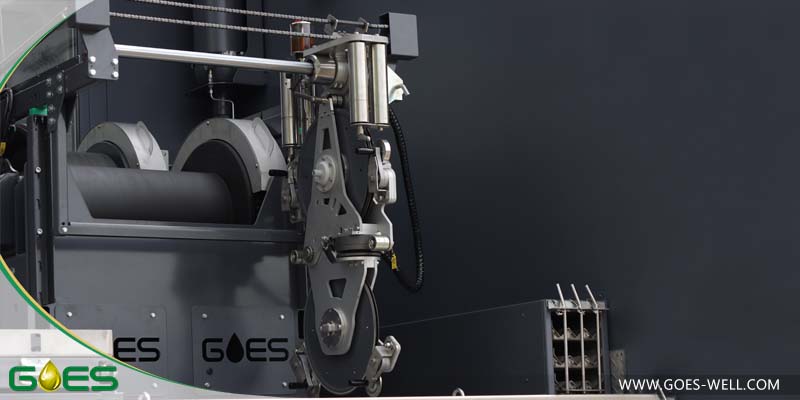

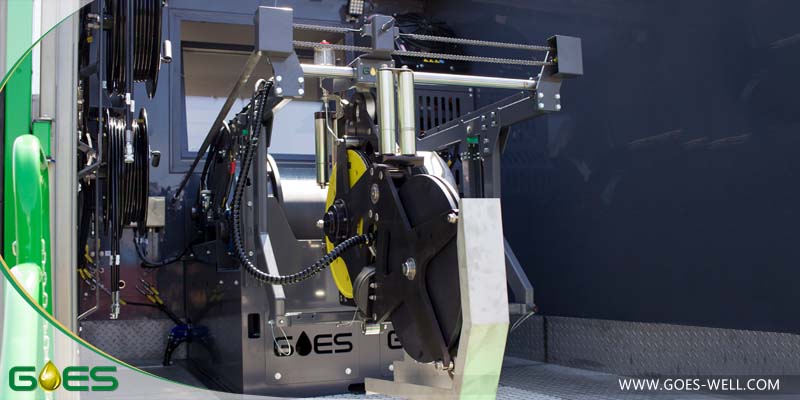

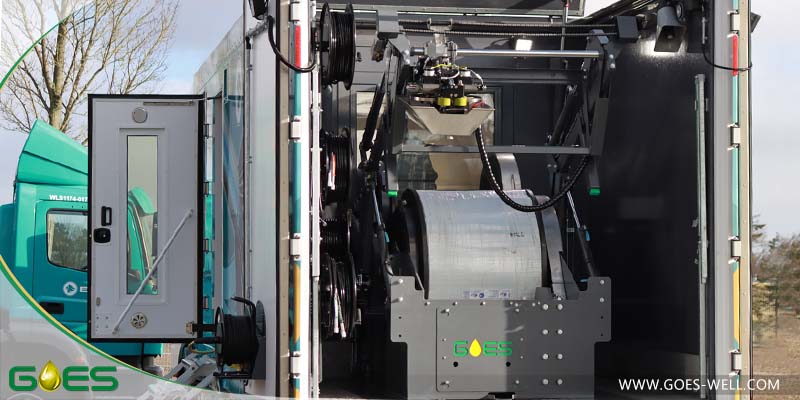

SLICKLINE / WIRELINE CASED HOLE COMBI UNIT CONTAINER

ELECTRIC OR HYDRAULIC DRIVEN

ELECTRIC OR HYDRAULIC DRIVEN

Copyright © GOES GmbH 2024